Squares

AI-POWERED TOOL

maintenance logs from

all types of heavy and

light-duty equipment

sprinkler seal leakage

language

processing

machine-readable

format

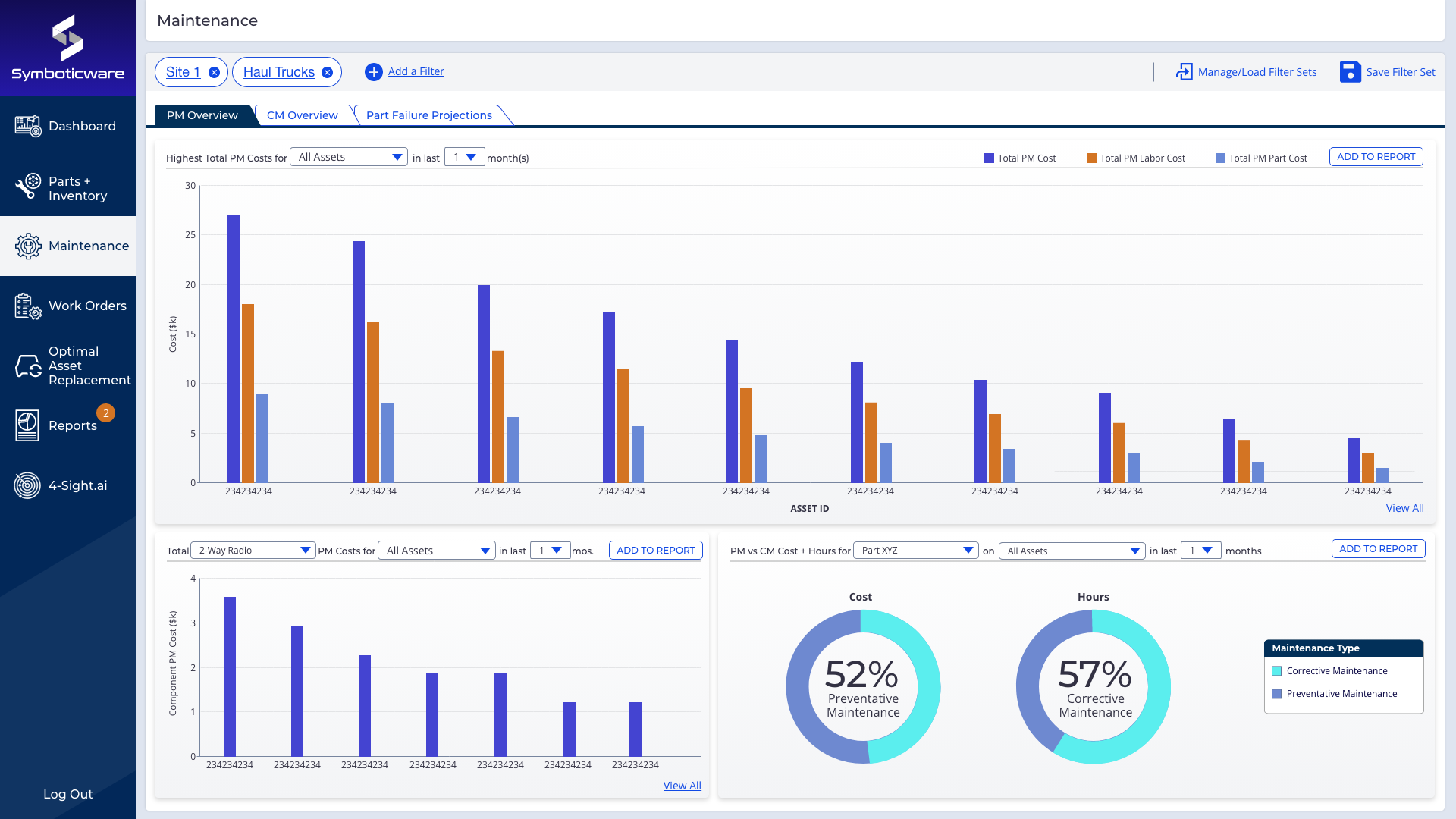

COMPLETE INSIGHT INTO MAINTENANCE

Squares empowers fleet maintenance by leveraging natural language processing to data points from intricate maintenance logs written by maintenance technicians, transforming them into valuable, actionable insights for efficient operations and safety

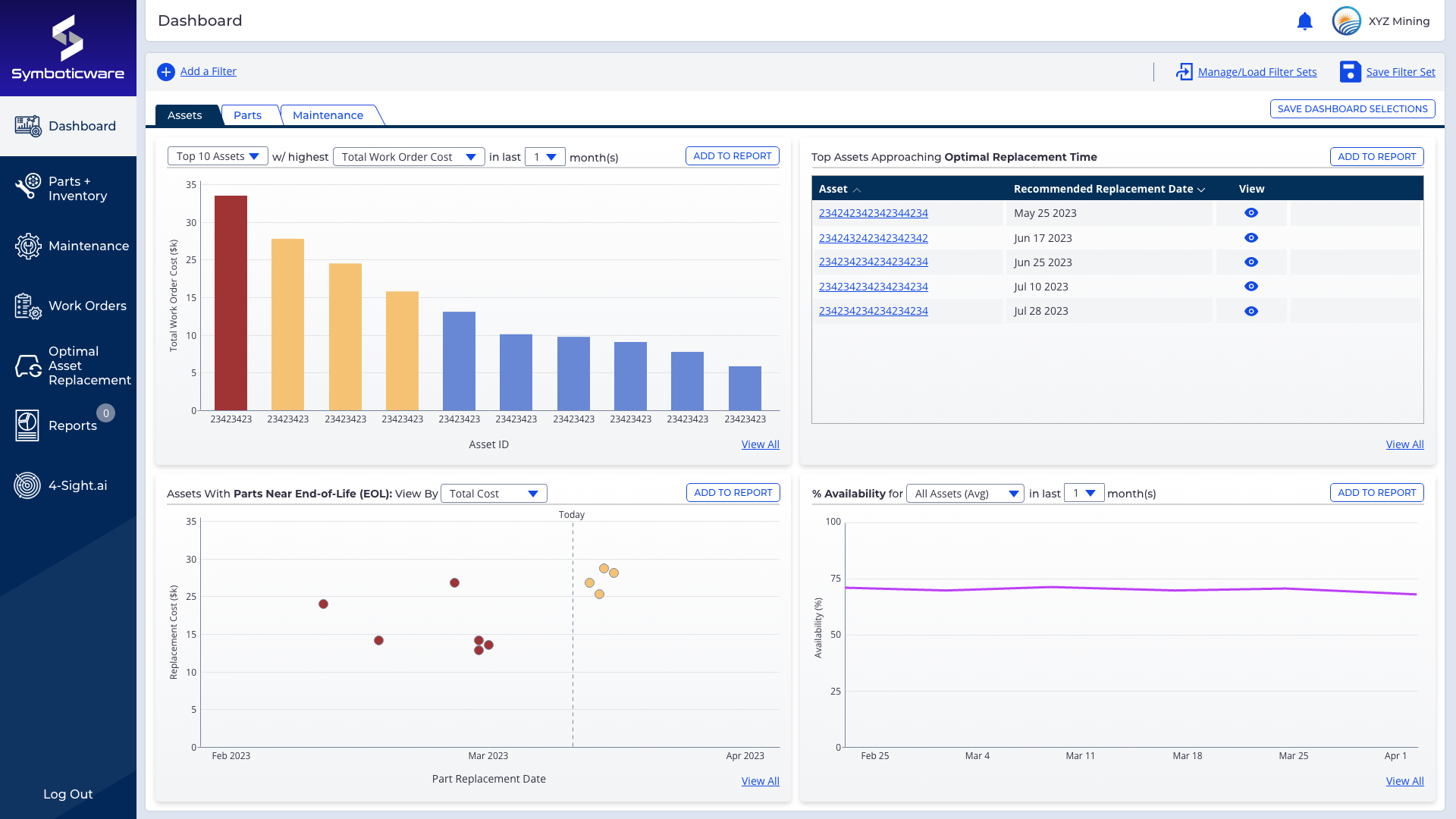

ANALYZE MULTIMILLION MAINTENANCE RECORDS

Squares revolutionizes equipment maintenance in the mining industry, where it accounts for up to 50% of operational expenses. Using advanced Natural Language Processing functionality (NLP), Squares unlocks the insights in maintenance logs, which were previously inaccessible due to their messy and inconsistent format.

This transformative analysis capability paves the way for unprecedented efficiency and cost optimization.

INDUSTRY’S FASTEST-VALUE

Squares delivers the fastest value in the industry thanks to its seamless, hardware-free integration. Simply connect it with your existing ERP system or upload the maintenance data, and leverage actionable insights within minutes. Squares continues to analyze your data in the background, ensuring continuous insights and optimization for the fleet operations.

MITIGATE FAILURE RISKS

Through analyzing maintenance logs, Squares uncovers crucial patterns in equipment maintenance and failures. This enables accurate survivability analysis, helping fleet managers decide the optimal time to schedule maintenance. By anticipating equipment failures before they occur, Squares minimizes unscheduled downtime and maximizes operational efficiency.

LEVERAGE MAINTENANCE DATA

By harnessing the power of AI and data accessibility, mining operations can drastically improve efficiency, potentially saving hundreds of liters of diesel fuel per truck per hour. Our transformative technology enhances safety, streamlines decision-making, drives innovation and paves the way for sustainable growth in an industry that is the backbone of the global economy.